1. Bioinspired layered materials with superior mechanical performance

Qunfeng Cheng, Lei Jiang, Zhiyong Tang Acc Chem Res. 2014 Apr 15;47(4):1256-66.doi: 10.1021/ar400279t.Epub 2014 Mar 17.

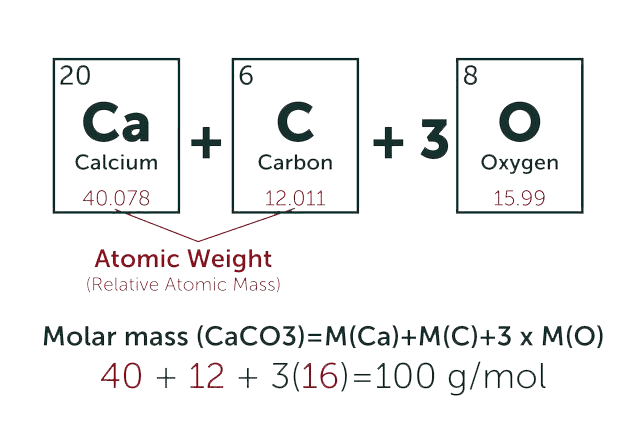

Nature has inspired researchers to construct structures with ordered layers as candidates for new materials with high mechanical performance. As a prominent example, nacre, also known as mother of pearl, consists of a combination of inorganic plates (aragonite calcium carbonate, 95% by volume) and organic macromolecules (elastic biopolymer, 5% by volume) and shows a unique combination of strength and toughness. Investigations of its structure reveal that the hexagonal platelets of calcium carbonate and the amorphous biopolymer are alternatively assembled into the orderly layered structure. The delicate interface between the calcium carbonate and the biopolymer is well defined. Both the building blocks that make up these assembled layers and the interfaces between the inorganic and organic components contribute to the excellent mechanical property of natural nacre. In this Account, we summarize recent research from our group and from others on the design of bioinspired materials composed by layering various primitive materials. We focus particular attention on nanoscale carbon materials. Using several examples, we describe how the use of different combinations of layered materials leads to particular properties. Flattened double-walled carbon nanotubes (FDWCNTs) covalently cross-linked in a thermoset three-dimensional (3D) network produced the materials with the highest strength. The stiffest layered materials were generated from borate orthoester covalent bonding between adjacent graphene oxide (GO) nanosheets, and the toughest layered materials were fabricated with Al2O3 platelets and chitosan via hydrogen bonding. These new building blocks, such as FDWCNTs and GO, and the replication of the elaborate micro-/nanoscale interface of natural nacre have provided many options for developing new high performance artificial materials. The interface designs for bioinspired layered materials are generally categorized into (1) hydrogen bonding, (2) ionic bonding, and (3) covalent bonding. Using these different strategies, we can tune the materials to have specific mechanical characteristics such as high strength, excellent strain resistance, or remarkable toughness. Among these design strategies, hydrogen bonding affords soft interfaces between the inorganic plates and the organic matrix. Covalent cross-linking forms chemical bonds between the inorganic plates and the organic matrix, leading to much stronger interfaces. The interfaces formed by ionic bonding are stronger than those formed by hydrogen bonding but weaker than those formed by covalent bonding.

2. Aqueous carbonation of peridotites for carbon utilisation: a critical review

Muhammad Imran Rashid, Emad Benhelal, Leo Anderberg, Faezeh Farhang, Timothy Oliver, Mark Stuart Rayson, Michael Stockenhuber Environ Sci Pollut Res Int. 2022 Oct;29(50):75161-75183.doi: 10.1007/s11356-022-23116-3.Epub 2022 Sep 21.

Peridotite and serpentinites can be used to sequester CO2 emissions through mineral carbonation. Olivine dissolution rate is directly proportional with temperature, presence of CO2, surface area of mineral particles and presence of ligands and is inversely proportional to pH. Olivine dissolution is better under air flow and increases seven times when rock-inhibiting fungus (Knufia petricola) is used. Olivine dissolution retards as silica layers form during reaction. Sonication, acoustic and concurrent grinding using various grinding medias have been used to artificially break these silica layers and achieve high magnesium extraction. Wet grinding using 50 wt.% ethanol enhanced CO2 uptake of dunite 6.9 times and CO2 uptake of harzburgite by 4.5 times. The best economical process is single-stage concurrent grinding at 130 bar, 185 °C, 15 wt.% solids and 50 wt.% grinding media (zirconia) using 0.64 M NaHCO3. Ratio of grinding media to feed should not be less than 3:1. Yield increases with temperature, pressure, time of reaction, pH and rpm and using additives and grinding media and reducing particle size. This review aims to investigate the progress from 1970s to 2021 on aqueous mineral carbonation of olivine and its naturally available rocks (harzburgite and dunite). This paper comprehensively reviews all aspects of olivine carbonation including olivine dissolution kinetics, effects of grinding and concurrent grinding, thermal activation of olivine feedstock (dunites and harzburgites) as well as chemistry of olivine mineral carbonation. The effects of different reaction parameters on the carbonation yield, role of mineral carbonation accelerators and costs of mineral carbonation process are discussed.

3. The evolution of the marine carbonate factory

Jiuyuan Wang, Lidya G Tarhan, Andrew D Jacobson, Amanda M Oehlert, Noah J Planavsky Nature. 2023 Mar;615(7951):265-269.doi: 10.1038/s41586-022-05654-5.Epub 2023 Feb 22.

Calcium carbonate formation is the primary pathway by which carbon is returned from the ocean-atmosphere system to the solid Earth1,2. The removal of dissolved inorganic carbon from seawater by precipitation of carbonate minerals-the marine carbonate factory-plays a critical role in shaping marine biogeochemical cycling1,2. A paucity of empirical constraints has led to widely divergent views on how the marine carbonate factory has changed over time3-5. Here we use geochemical insights from stable strontium isotopes to provide a new perspective on the evolution of the marine carbonate factory and carbonate mineral saturation states. Although the production of carbonates in the surface ocean and in shallow seafloor settings have been widely considered the predominant carbonate sinks for most of the history of the Earth6, we propose that alternative processes-such as porewater production of authigenic carbonates-may have represented a major carbonate sink throughout the Precambrian. Our results also suggest that the rise of the skeletal carbonate factory decreased seawater carbonate saturation states.